- The correct use of the air shower can effectively control bacteria and dust

In much production work, due to the high requirements of the product, it is usually carried out under aseptic conditions during production and processing. Due to the presence of some impurities and bacterial particles in the working environment, this...

- Air filter replacement cycle for air shower room

You may find the performance of the filter in the air shower is particularly good after using it. Compared with other filters, it contains the primary air filter and the air filter, and has a two-in-one function. So let me introdu...

- The angle requirements of the air outlet of the air shower room

Press the up and down keys for about 10 seconds, the Chongqing air shower time can be adjusted. So what are the requirements?

The single-person double-air shower is a special passage set up for the staff to enter and exit the clean area, which ca... - The reason why the air shower room needs the primary filter and the high efficiency filter

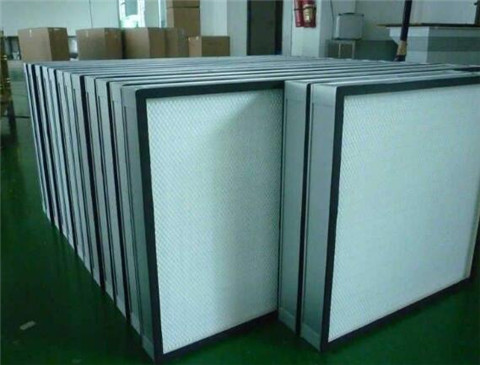

The air shower room in Chongqing must be equipped with primary efficiency filters and high efficiency filters to achieve the dust removal effect. The air shower room has a voice prompt system, which prompts people to complete the entire blowing and d...

- Clean room and sterile room needing to install air shower

The general air shower room is a special channel specially set up for work management personnel and materials to enter the clean room. The main purpose of the company is to reduce the dust and bacteria we bring into the clean room when the staff and mater...

- The importance of airtight performance to stainless steel air shower

Nowadays, purification equipment is increasingly used in the production industry. The air shower room serving as an important throat of the clean room, when people or objects entering and exiting the clean room, the air shower room will be ...

The importance of airtight performance to stainless steel air shower

information sources:www.xqfjhgc.com | Release time:2021-06-18

Nowadays, purification equipment is increasingly used in the production industry. The air shower room serving as an important throat of the clean room, when people or objects entering and exiting the clean room, the air shower room will be the place where it is needed. On the other hand, the air shower room is also used as a closed clean room for the air room.

Generally, differential pressure control is a method to maintain clean room air quality and prevent cross-contamination with the external environment. The air shower room serves as an airtight room and is an essential channel for entering the clean room. The air shower has two doors that cannot be opened at the same time. Its purpose is to cut off the air in two different clean environments and prevent contaminated air from entering the clean area.

Even with the use of a differential pressure control system, the clean room and air shower room cannot guarantee that the positive pressure is relative to the external environment under all circumstances, in the event that the air supply system of the purification equipment breaks down or the resistance is too large. After long-term use, positive pressure cannot be maintained. At this time, good airtightness of the air shower room is very important, and it can prevent the external polluted air from leaking into the clean room through the gap of the partition wall or the gap between the doors and windows.

The dust-free door installed in the air shower room adopts a sealed distribution foaming process. The distribution seal is installed inside the door, and the distribution amount can be adjusted according to the gap size. Therefore, the foaming height and gap should be better controlled, and the air tightness is better. Compared with traditional sealing strips, it has a long life and has the advantages of odorless. Traditional sealing strips are easy to deform, fall off, wear and have poor elasticity.

Related articles

Related products